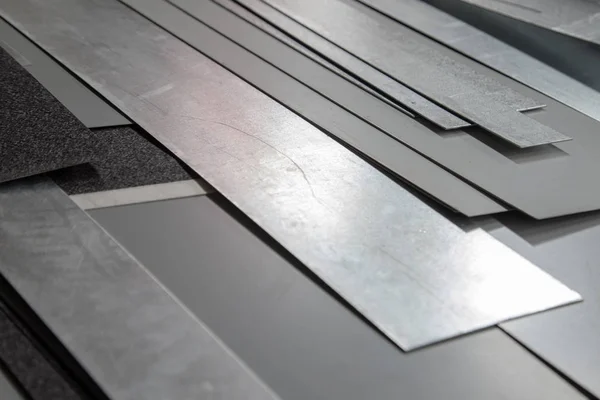

In the vast landscape of automobile manufacturing, metal stamping automotive stands out as a crucial process that significantly impacts the efficiency and quality of vehicle production. This technique involves the shaping of flat metal sheets into specific forms through the use of a die and stamping press. As the U.S. car industry continues to evolve, metal stamping plays an indispensable role, offering numerous advantages that streamline production processes and enhance product quality.

Metal stamping automotive is revered for its precision and efficiency. This process ensures that every component of a vehicle meets high standards of quality and consistency, which is essential in an industry where safety and reliability are paramount. Here are some key benefits of metal stamping in the automotive sector:

Cost Efficiency: Metal stamping is highly economical, especially in mass production. The process reduces labor costs and material waste, allowing manufacturers to produce high volumes of parts at a lower cost per unit. This cost-effectiveness is a significant advantage in maintaining competitive pricing in the automotive market.

Precision and Consistency: The use of advanced technology in metal stamping ensures that each part is produced with exact precision. This consistency is crucial for the automotive industry, where even the smallest discrepancies can affect vehicle performance and safety.

Speed and Scalability: Metal stamping allows for rapid production of components, which is vital for meeting the high demands of the automotive industry. The scalability of this process means that manufacturers can quickly adjust production levels to respond to market needs or changes in consumer demand.

Versatility: This process is not limited to a single type of metal or component. Metal stamping can be applied to various materials, including steel, aluminum, and copper, allowing for the creation of a wide range of parts and components, from body panels to intricate engine parts.

Enhanced Safety and Durability: The precision and quality control inherent in metal stamping contribute to the safety and durability of automotive parts. By ensuring that components fit perfectly and function as intended, manufacturers can produce vehicles that are not only safe but also long-lasting.

For more detailed insights into how metal stamping benefits the transportation industry, you can explore additional resources on metal stamping automotive.

In conclusion, metal stamping automotive offers a multitude of benefits that are crucial for the U.S. car industry. From cost efficiency and precision to speed and versatility, this manufacturing technique is integral to producing high-quality, safe, and reliable vehicles. As the automotive industry continues to advance, the role of metal stamping will undoubtedly remain central, ensuring that manufacturers can meet the ever-growing demands of consumers while maintaining high standards of quality and safety. By leveraging the advantages of metal stamping, the U.S. car industry can continue to thrive in an increasingly competitive global market.