There are different options in zinc electroplating processes, each offering different benefits for specific applications. The use of zinc alkaline plating is ideal when the part or component is going to be further finished with paint or powder coating, which is common in the automotive, aerospace and equipment manufacturing industries.

However, zinc alkaline plating is also suitable as a finish left on its own. For many internal parts and components, this is a low-cost option, eliminating the need for further finishing after the protective coating is applied to the steel.

A Brief History

All types of zinc electroplating are considered a superior option to the older cadmium electroplating processes or those containing cyanide. Not only does the zinc offer no concerns about toxicity, but it is also fully RoHS compliant, a critical component for anyone exporting parts and components or equipment and machines.

The first use of the alkaline plating with cyanide-free zinc was started in the mid part of the 1960s. This was completed due to increased regulation of the waste material from electroplating facilities to address the risk of toxic materials in the environment. Further refinement and development of the process, as well as advanced controls of all factors in the plating process, make this a precise process that provides the coating to metals that is durable and resistant to damage from corrosion.

The Cost Efficiency of the Process

The use of the zinc cyanide-free alkaline plating made it a cost-effective option compared to many of the other processes developed at the same time. While it does require complete cleaning of the parts or components before the plating process, it provides a superior quality, precision application of the zinc across the surfaces of the metal.

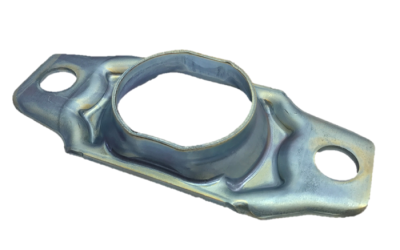

This includes in deep recesses in the design of the part or component, as well as on angles and internal surfaces. This covering ability, as well as the precision application, make it the ideal solution for many parts.