Load cell telemetry systems are advanced measurement solutions designed to transmit force or weight data wirelessly from a load cell to a remote monitoring or control system. These systems eliminate the need for physical wiring, making them ideal for applications where cables are impractical, unsafe, or prone to damage. By combining load cells with wireless transmitters and receivers, telemetry systems enable accurate, real-time data collection in dynamic and challenging environments.

How Load Cell Telemetry Systems Work

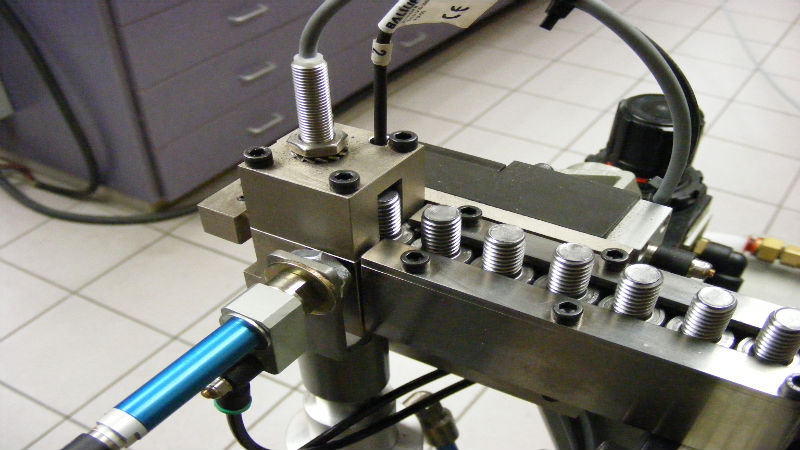

A load cell telemetry system typically consists of a load cell, a signal conditioning unit, a wireless transmitter, and a receiver or data acquisition device. The load cell converts mechanical force into a small electrical signal, which is then amplified and conditioned to ensure accuracy. This conditioned signal is transmitted wirelessly—often via radio frequency (RF), Bluetooth, or industrial wireless protocols—to a receiver that displays, records, or processes the data.

Because the transmission occurs without cables, telemetry systems are especially useful in rotating, moving, or hard-to-reach components where traditional wiring would fail or introduce measurement errors.

Key Advantages of Telemetry Systems

One of the primary benefits of load cell telemetry systems is mobility. They allow continuous monitoring of forces on rotating shafts, cranes, vehicles, and test rigs without signal interruption. This reduces wear and tear associated with cable movement and significantly lowers maintenance requirements.

Safety is another major advantage. Wireless transmission minimizes trip hazards and reduces the risk of cable damage in high-motion or hazardous environments. Additionally, telemetry systems can transmit data over long distances, allowing operators to monitor loads from a safe and convenient location.

These systems also offer high signal integrity. Modern telemetry technology includes digital signal processing, error correction, and noise filtering to ensure accurate and stable data transmission, even in electrically noisy industrial settings.

Applications Across Industries

Load cell telemetry systems are widely used in aerospace testing, automotive development, construction, and heavy equipment monitoring. In rotating machinery, such as drive shafts and torque arms, telemetry allows precise force measurement without restricting movement.

In structural testing and research environments, telemetry systems enable real-time monitoring of loads applied to bridges, towers, and mechanical assemblies. They are also commonly used in crane load monitoring, off-road vehicle testing, and fatigue testing, where constant movement makes wired connections unreliable.

Factors to Consider When Choosing a System

When selecting a load cell telemetry system, factors such as transmission range, sampling rate, power consumption, and environmental durability are critical. Battery life and power management are especially important for long-term monitoring applications. Compatibility with existing data acquisition or control systems should also be evaluated to ensure seamless integration.

The Importance of Load Cell Telemetry

Load cell telemetry systems provide flexibility, accuracy, and reliability in situations where wired measurement is not feasible. By enabling wireless data transmission without compromising precision, these systems support safer operations, better diagnostics, and improved performance across a wide range of industrial and research applications.