Large manufacturing facilities are the backbone of many industries, where continuous operation and safety are imperative. When it comes to maintaining high standards in electrical systems, many facility managers search for Industrial Electrical Contractors Atlanta GA to address their needs. These professionals play a crucial role in ensuring that complex industrial environments remain safe, efficient, and reliable.

The Importance of Specialized Electrical Expertise

Manufacturing facilities require sophisticated electrical systems to power heavy machinery, lighting, automation, and safety devices. The expertise of industrial electrical contractors is essential for several reasons:

• Complex System Design: Industrial settings demand custom electrical layouts tailored to specific processes and equipment. Contractors ensure that systems are designed to handle high loads and meet production requirements.

• Code Compliance: Electrical codes and safety regulations are strict in industrial environments. Contractors stay updated on local and national codes, ensuring all installations meet or exceed these standards.

• Preventive Maintenance: Regular inspections and proactive maintenance help identify potential issues before they cause costly downtime or safety hazards.

Safety Protocols and Risk Management

Safety is a top priority in manufacturing facilities, where electrical hazards can lead to severe injuries or production losses. Industrial electrical contractors in Atlanta implement a range of safety measures to mitigate risks:

1. Thorough Risk Assessments: Contractors conduct detailed site assessments to identify hazards and develop strategies to minimize them.

2. Lockout/Tagout Procedures: Strict adherence to lockout/tagout protocols protects workers during equipment servicing and repairs.

3. Personal Protective Equipment (PPE): Workers are trained and equipped with appropriate PPE to prevent electrical shock and arc flash injuries.

4. Ongoing Safety Training: Continuous education ensures that all personnel are aware of the latest safety practices and emergency procedures.

Ensuring Reliability and Operational Continuity

Reliability is critical in manufacturing, where even brief power interruptions can disrupt production lines and result in significant financial losses. Industrial electrical contractors Atlanta GA achieve reliability through:

• Redundant Systems: Installing backup generators, uninterruptible power supplies (UPS), and dual-feed power sources ensures operations continue during outages.

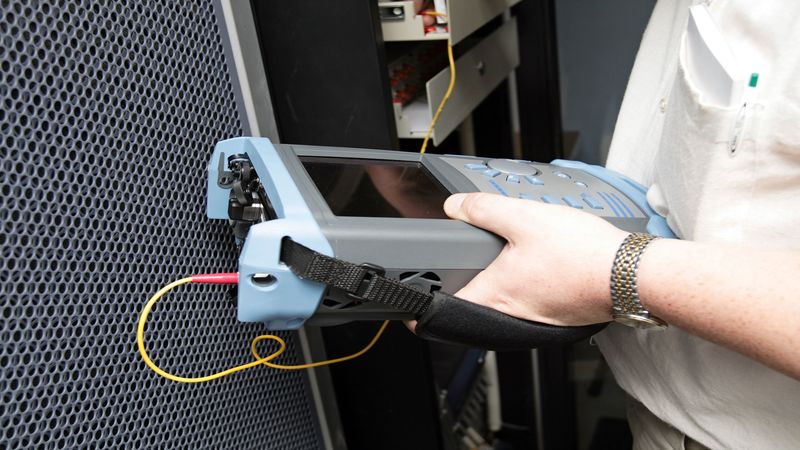

• Routine Testing: Regular testing of electrical panels, circuit breakers, and emergency systems helps detect vulnerabilities early.

• Upgrading Legacy Systems: Modernizing outdated wiring and control systems improves efficiency and reduces the likelihood of unexpected failures.

Benefits of Professional Industrial Electrical Services

Partnering with experienced contractors brings several advantages to manufacturing operations:

• Reduced Downtime: Prompt troubleshooting and repairs minimize production interruptions.

• Enhanced Safety: Comprehensive safety measures protect both personnel and equipment.

• Cost Savings: Preventive maintenance and efficient system design lower energy costs and reduce the need for emergency repairs.

• Regulatory Compliance: Proper documentation and adherence to codes help avoid fines and legal issues.

In summary, the role of industrial electrical contractors in Atlanta GA, is vital in maintaining the safety and reliability of large manufacturing facilities. Their specialized knowledge, adherence to safety standards, and commitment to operational excellence ensure that manufacturing processes run smoothly and securely. Facility managers seeking peace of mind and uninterrupted productivity should consult skilled professionals for their electrical needs. For more information or to schedule a consultation, reach out to a trusted industrial electrical contractor in your area today.