Halar, or ECTFE (Ethylene ChloroTriFluoroEthylene) as it is widely known, is a thermoplastic fluoropolymer coating. Halar is used in many industries but is particularly popular in the chemical processing industry. This high-quality, protective coating has the unique ability to resist chemicals and is one of the most popular coatings for heavy duty corrosion applications.

All coatings are designed to protect. However, certain coatings such as Halar, have the added advantage of meeting high-performance industrial needs.

A Smooth Finish Provides Additional Protection

Many companies choose a Halar coating for their application needs because, in addition to its ability to resist chemicals, it is also a top choice for providing a smooth finish, which stops any particles from accumulating or getting caught on the surface. This finish also protects the coated item against tiny pinholes or cracks.

A Coating With Outstanding Properties

* Halar provides excellent corrosion protection

* It has excellent thermal properties

* It offers low permeability

* It is resistant to a broad range of chemicals

* Durable and wear resistant

* Has non-stick properties

* Excellent weather ability

* Dries to a smooth, pore-free finish

* Flame resistant

* Known for its purity

Resistant to Solvents, Acids, Heat and Fire

halar coating offers incredible protection in aggressive environments. It is extremely resistant to solvents and acids such as Hydrofluoric, Sulfuric and Nitric Acid. It also resists ammonium hydroxide, alkalines, hydrogen peroxide and ozone. Halar is unbelievably durable and is also resistant to heat and fire. Naturally, this makes it an obvious choice to coat cables and wires. In fact, it is one of the most highly used coatings in semiconductors and microelectronics.

Ideal Coating for Pharmaceutical and Chemical Industries

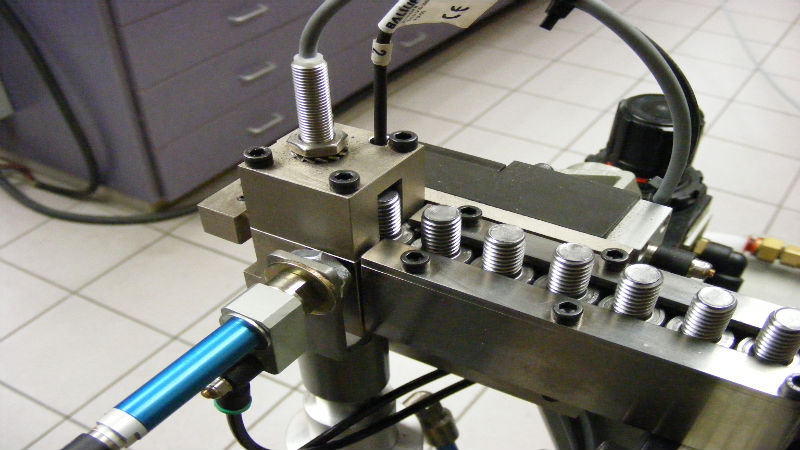

Any product that comes in contact with highly corrosive or ultrapure chemicals is likely to be covered with a protective Halar coating. Applied to filter vessels, tanks, pumps, pipes and valves, this coating is used on any vessel used to store or transport corrosive media. It is also used for filters, electroplating and exhaust hoods. Halar is suitable for high purity systems in the pharmaceutical and biotech industries. It is also used to coat stainless steel exhaust ducts that handle corrosive exhaust in clean rooms.

Fluid Handling & Waste Disposal

You will find Halar coatings on instruments and equipment used in most industries that deal with fluid handling and waste disposal. The delivery, processing and storing of hazardous fluids demands equipment that can withstand extreme temperatures and harsh chemicals. Halar has these capabilities.

A highly acclaimed expert in the custom coating industry, Quality Coatings Inc. has been providing clients with industrial coating solutions and superior workmanship for over two decades. Their rapid response time and excellent customer service are unparalleled.