Small focal spot X-ray tubes are an important part of producing quality x-rays. Without them, the results would be inaccurate, posing challenges for the industry in producing accurate images, analyses, and measurements. We explore a few key areas where these tubes improve X-ray precision.

X-ray Imaging

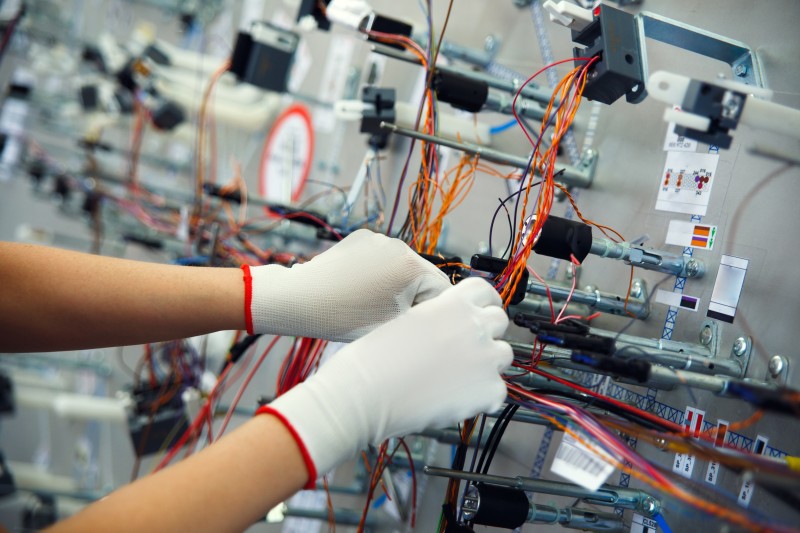

Small focal spot X-ray tubes increase image sharpness because of their small focal points. Industry standards vary on properly measuring the size of these focal spots, and some have a significant deviation. This causes some tubes to include less accurate oblong focal spots that reduce image quality. The solution to this problem is to use X-ray tubes custom designed and manufactured for better end results and that don’t mix standards.

X-ray Fluorescence (XRF)

This occurs when a material is excited from high-energy x-rays or gamma rays. Used in the investigation of metals and other research, this is an important analysis tool. XRF analyzers measure this secondary X-ray to quantify and qualify the composition of many materials. An X-ray tube is an important part of this analyzer.

XRF tubes need to be robust enough to last between four and six years and up to 30,000 hours of use. However, two primary factors reduce the life of these tubes. First, inadequate cooling increases material stress through consistent expansion. Second, a high variance in power levels will place different stresses on tube filaments, reducing their life and effectiveness. It is important to select an XRF tube that withstands these conditions.

Thickness Gauging

Another common application for RDF tubes is measuring the thickness of materials, including adhesive tape, film, and other coated materials. Some of these measurements are of simple, one-layer coatings, while others comprise multilayer measurements. It is important to use an XRF tube that has strong stability characteristics which enable accurate, fast, and reliable measurements.

Contact Micro X-ray Inc. when you’re in need of small focal spot X-ray tubes.