In today’s fast-paced industrial landscape, optimizing workflow is essential for maintaining both product quality and operational efficiency. Whether in the food and beverage sector, pharmaceuticals, chemicals, or construction, industries are constantly searching for solutions that streamline processes and minimize downtime. One crucial component that has proven indispensable across various sectors is Sieving Equipment. This technology not only ensures consistent particle separation but also enhances productivity, safety, and compliance with industry standards.

The Importance of Effective Particle Separation

Reliable particle separation is more than just a quality control measure—it is fundamental to the integrity of the entire production process. Inconsistent or inadequate separation can lead to contamination, product recalls, and increased costs. By integrating advanced sieving solutions, companies can achieve precise particle sizing, remove unwanted contaminants, and ensure that only materials of the desired grade progress through the workflow.

Key Benefits of Advanced Sieving Solutions

Modern sieving technologies offer a range of advantages that go beyond basic separation. Here are some of the most significant benefits:

• Enhanced Product Quality: By ensuring uniform particle size distribution, sieving equipment helps maintain the desired texture, appearance, and performance of products.

• Increased Throughput: Automated systems can process large volumes of material efficiently, reducing bottlenecks and boosting overall productivity.

• Reduced Waste: Accurate separation minimizes material loss, leading to cost savings and more sustainable operations.

• Improved Workplace Safety: Dust-tight designs and enclosed systems limit exposure to hazardous materials, protecting both workers and the environment.

• Compliance with Standards: Consistent sieving ensures that products meet stringent industry regulations and quality benchmarks.

Types of Sieving Equipment and Their Applications

There is a wide variety of sieving solutions available, each tailored to specific industrial needs. Understanding the options can help businesses select the most suitable equipment for their unique requirements.

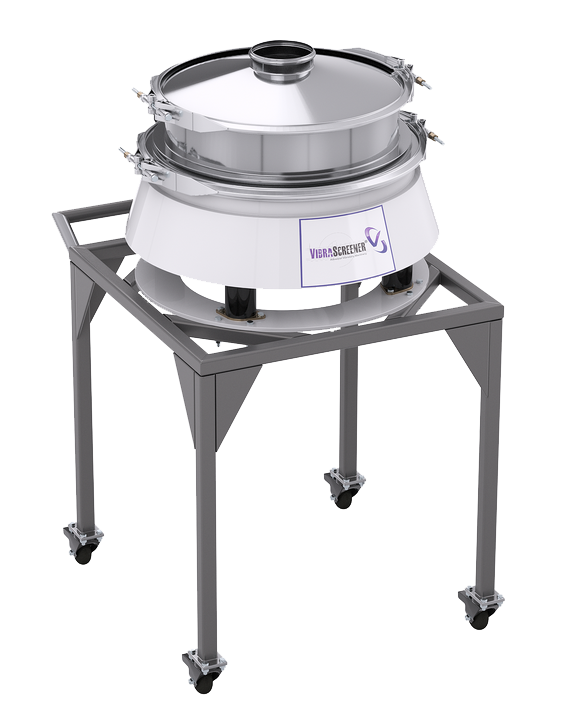

1. Vibratory Sifters: These machines use vibration to move material across a mesh screen, efficiently separating particles by size. They are ideal for high-volume applications in food processing, pharmaceuticals, and chemicals.

2. Centrifugal Sifters: Using centrifugal force, these sifters are well-suited for fine powders and materials that are difficult to screen using vibration alone.

3. Ultrasonic Sieves: Employing high-frequency sound waves, these systems are perfect for separating very fine particles and preventing mesh blinding.

4. Rotary Sieves: Commonly used in bulk solids processing, rotary sieves offer gentle handling for fragile materials.

Each type of equipment can be further customized with different mesh sizes, materials, and configurations to address specific challenges within a given industry.

Optimizing Workflow with Efficient Sieving Practices

Integrating the right sieving solution into your industrial workflow can yield significant improvements. Here are a few actionable strategies:

• Assess Material Characteristics: Consider particle size, moisture content, and flowability when selecting equipment.

• Automate Where Possible: Automation reduces manual handling, increases consistency, and frees up labor for other tasks.

• Prioritize Maintenance: Regular cleaning and inspection prevent blockages and equipment failures, ensuring uninterrupted operation.

• Monitor Performance: Use sensors and data analytics to track throughput and identify potential issues before they escalate.

By focusing on these practices, companies can maximize the return on investment from their sieving systems and maintain a competitive edge.

Elevating Industrial Operations with Reliable Particle Separation

Reliable particle separation is essential for industries seeking to improve workflow and maintain high standards of quality and safety. By choosing and implementing advanced sieving solutions tailored to specific operational needs, businesses can reduce waste, increase efficiency, and ensure compliance with industry regulations. Investing in modern sieving technologies is a proven strategy for achieving consistent results and supporting long-term growth in today’s demanding industrial environments.